Additive Manufacturing for Aerospace and Defense

Metal 3D Printing Solutions for Aerospace and Defense

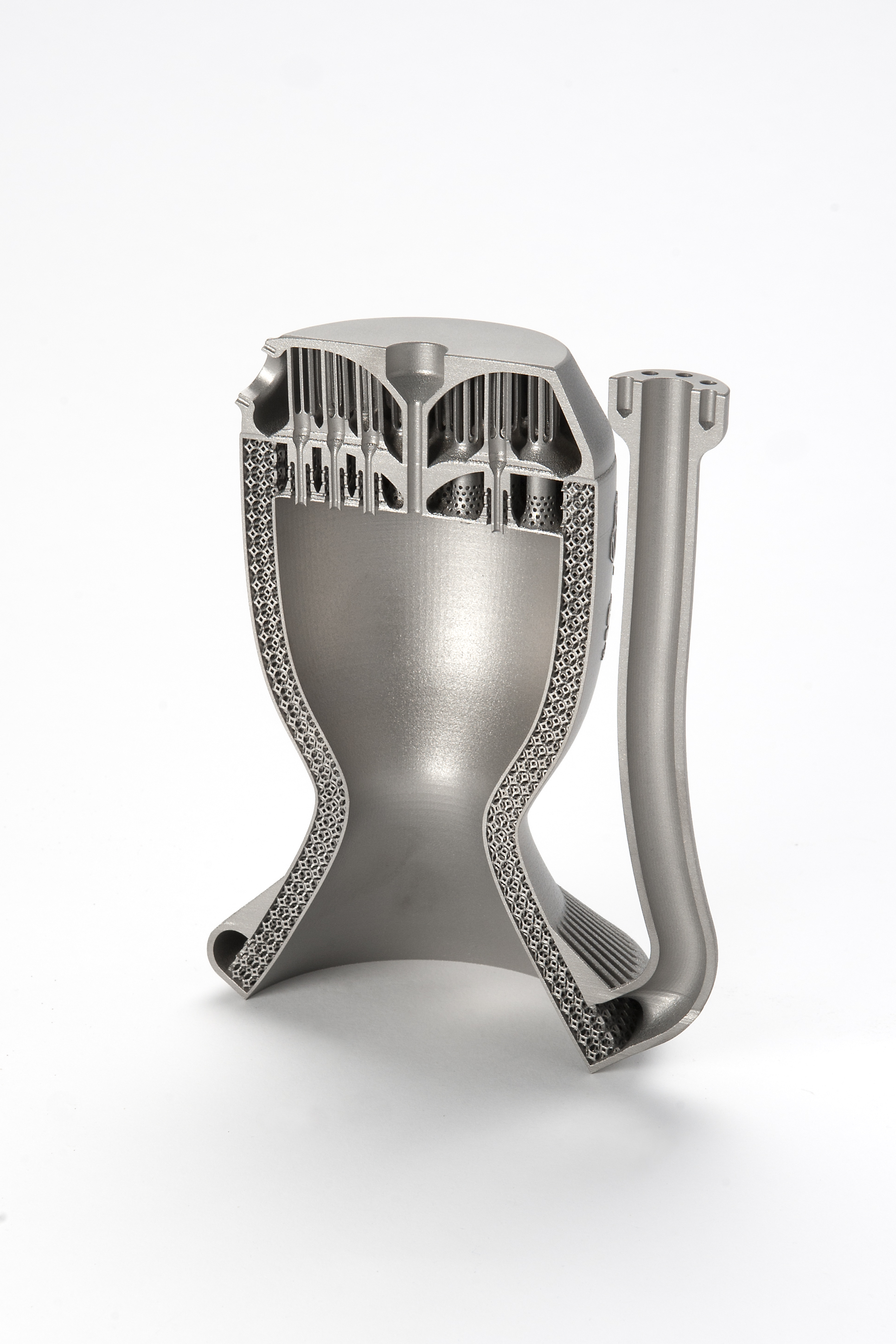

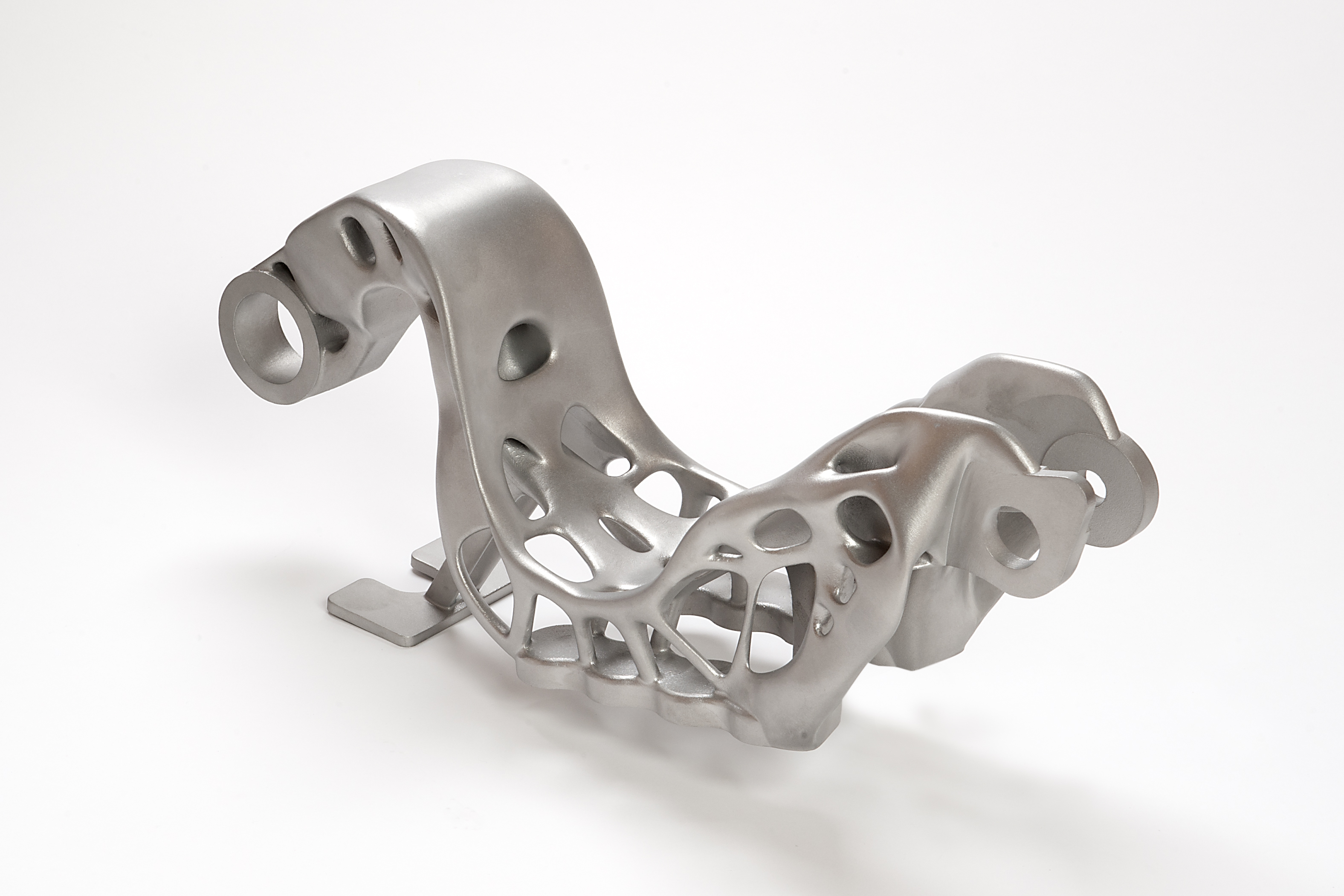

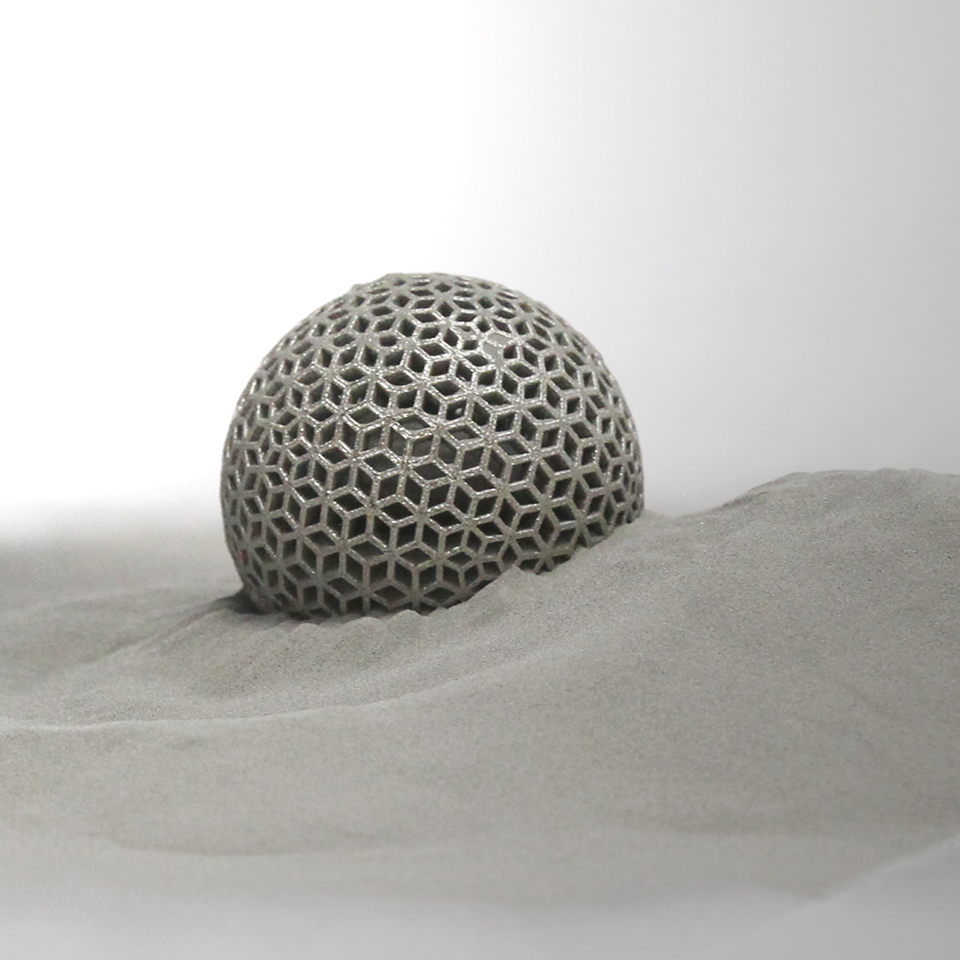

Take off with additive manufacturing for Aerospace and Defense. Nikon SLM Solutions Systems help meet stringent industry standard certification to make complex parts that cannot be machined and improve the performance and functionality of the component. Selective Laser Melting gives engineers the design freedom to consolidate parts to reduce mass and cost, ultimately making strategic weight decisions where needed.

Whether you are making one or many, the sky’s the limit – we help ensure your success with metal additive manufacturing. Find out more about the numerous manufacturing possibilities using SLM® technology in the Aerospace and Defense industry below.

SLM® Material for Aerospace & Defense Applications

Nikon SLM Solutions provides a wide range of suitable materials for the aerospace industry which meet the stringent requirements of aircraft engine manufacturers for metallographic and mechanical properties.

Our portfolio includes:

- Ni-Based Alloys: IN625, IN718 and HX

- Ti-Based Alloys: TIAl6V4

- Al-Based Alloys: AlSi10Mg

Selective Laser Melting Solutions for Aerospace Applications

Quality Standards for Aerospace Industry

We are experts when it comes to qualifying metal parts on our machines, and we are ready to help you each stage of the process. SLM Solutions supports aerospace projects with relevant documentation, certificates, pFMEAs, parameters, powders, aerospace tailored services and more. Allow us to share our knowledge with you to boost your metal additive manufacturing production, contact us today!