Additive Manufacturing for the Healthcare Industry

Metal 3D Printing for Healthcare

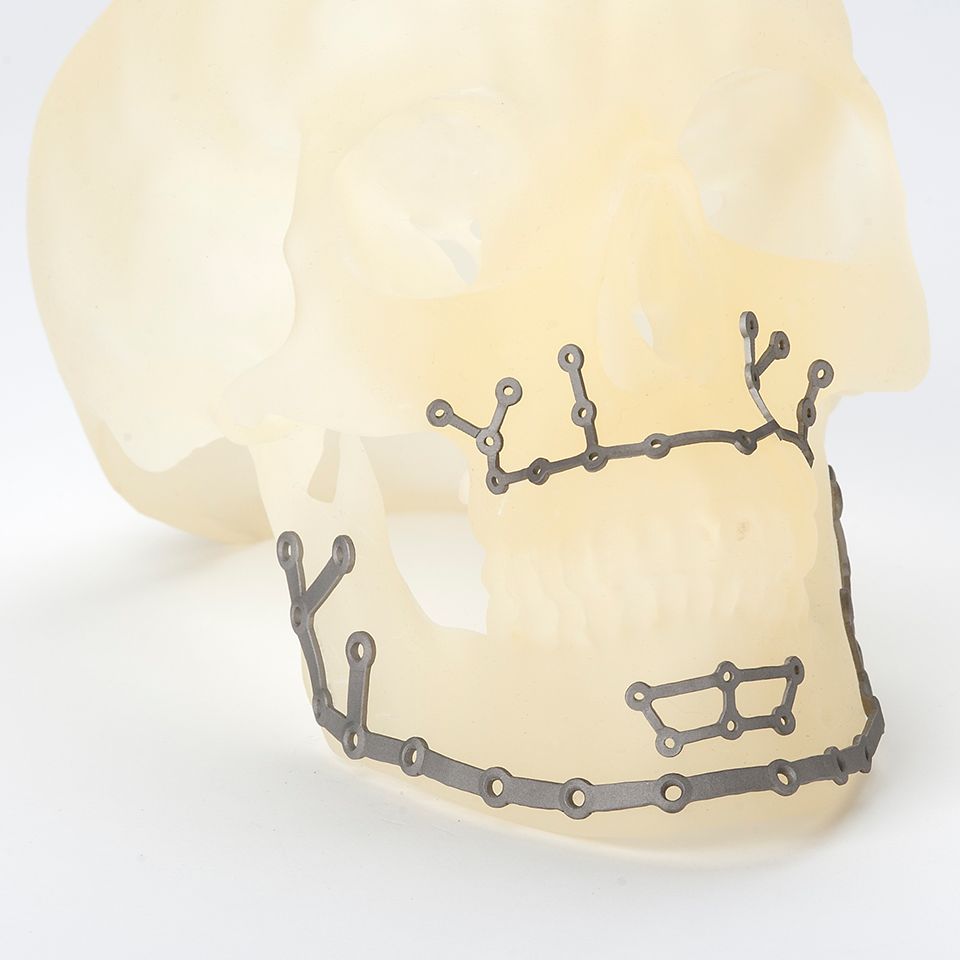

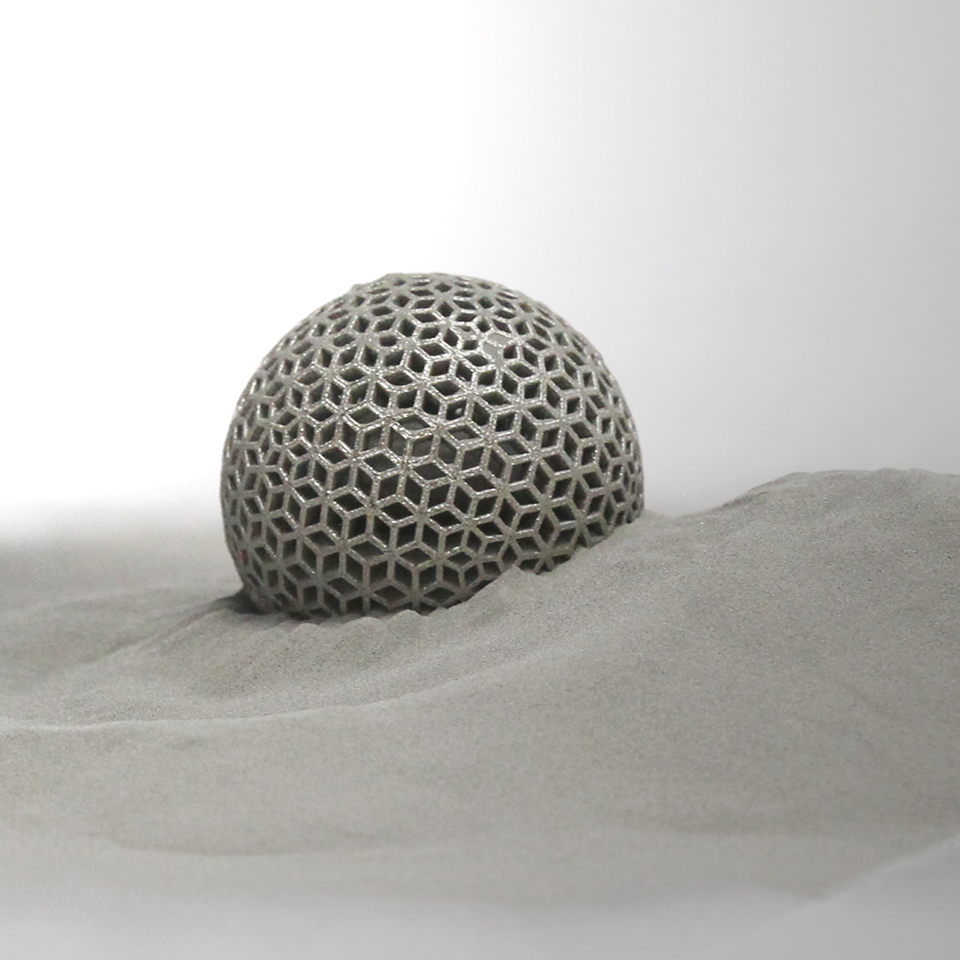

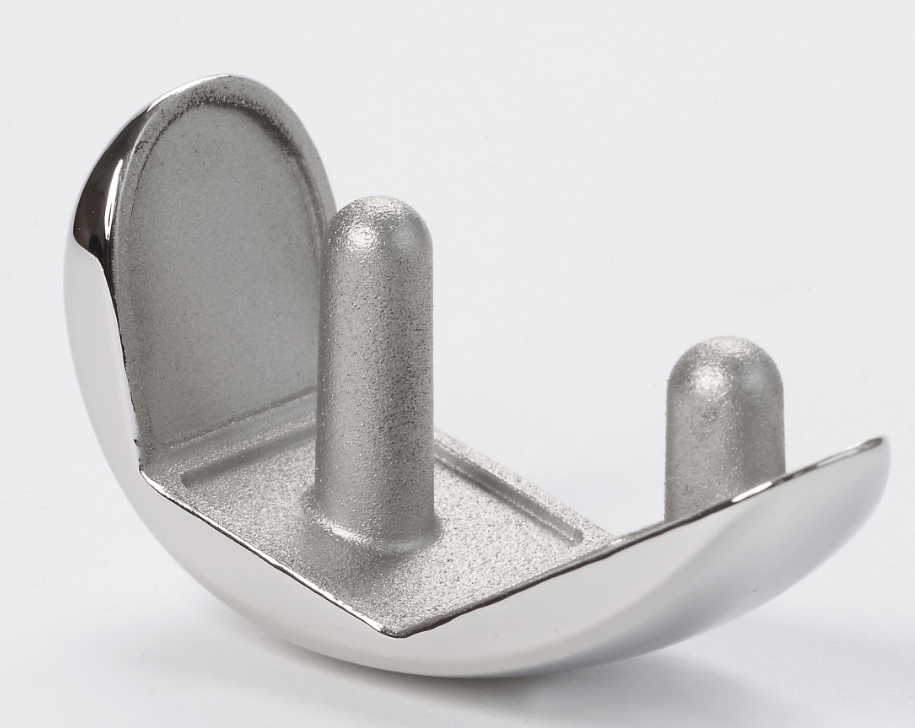

Medical device manufacturers are increasingly adopting metal additive manufacturing technology to produce a wide range of medical devices and dental prostheses. Selective Laser Melting is the ideal production technique to integrate function into medical device components, for example, printing surgical implants with lattice structures for enhanced osseointegration and reduced stress shielding. Designs optimized for the SLM® process, and those custom to patients’ anatomy, often create complex bionic geometries which can only be efficiently produced with Selective Laser Melting. SLM® technology provides productivity and cost advantages to users, compared to conventional manufacturing processes such as casting and machining.

Whether you are making one or many, experience tailored patient care with AM – we help ensure your success with metal additive manufacturing. Find out more about the numerous manufacturing possibilities using SLM® technology in the healthcare industry below.

SLM® Materials for Healthcare Applications

Nikon SLM Solutions offers a wide range of qualified metal powders for use on our selective laser melting systems and commonly utilized in the healthcare industry. All materials provided by Nikon SLM Solutions are qualified for their chemistry, spherical structure, particle size distribution, dryness and flowability. We offer validated process parameters for all biomaterials on all our machines.

- Ti-Based Alloys: Ti6Al4V Gd. 23, Ti (Grade 2)

- Co-Based Alloys: CoCr28Mo6, SLM® MediDent

- Stainless Steel: 316L (1.4404), 17-4PH (1.4542)

Other biomaterials are available on request.

Selective Laser Melting Solutions for Healthcare Applications

Quality Standards for Healthcare Industry

We are experts when it comes to qualifying metal parts on our machines, and we are ready to help you each stage of the process. Nikon SLM Solutions supports healthcare projects with relevant documentation, certificates, pFMEAs, parameters, powders, and more. Allow us to share our knowledge with you to boost your metal additive manufacturing production, contact us today!