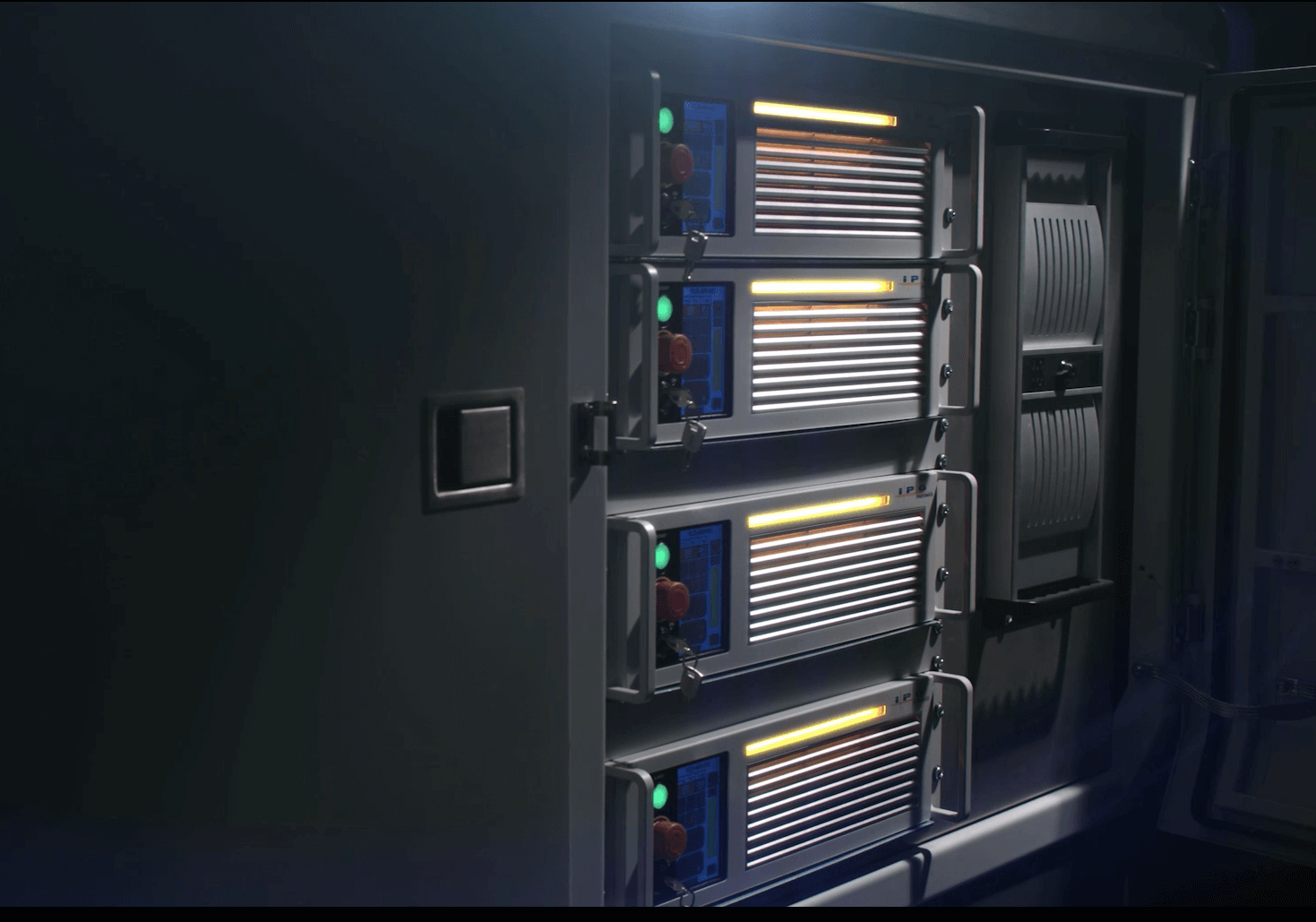

SLM®500

The first quad-laser metal system on the market, SLM®500 can integrate lasers independently or in parallel to increase build rates by 90% over twin laser configurations.

- 500 x 280 x 365 mm build envelope

- Multi-laser (twin or quad)

- Dedicated material

- Automated powder handling

- Turnkey system includes part removal station

SLM®500

The best performing, most efficient system in its class, the SLM®500 is designed to ensure operator safety and lower overall operational costs. Machine operator and powder are separated through a closed-loop powder handling strategy that includes an automated powder sieve and supply. Designed for serial production, exchangeable build cylinder enables shortest possible fire to fire times reducing downtimes of the machine to a minimum. The patented multi-laser overlap strategy ensures consistent material quality.

SLM®500 Real World Parts

SLM®500 Accessories

A byproduct of the welding process is submicronic soot and condensate, which can be pyrophoric by nature. The permanent filter module traps soot and condensate particles from the process gas stream in a sintered plate filter. The filter is purged with gas, the waste material coated with an inhibitor and dropped in a bin for dry disposal, while clean gas returns to the process chamber.

- Long-life filter ensures part quality throughout builds without interruption

- No changing of filter cartridges

- Reduced consumable costs

- Safer operation by avoiding loaded filter housing exchange

- Dry mixture waste disposal without hydrogen formation with reactive materials

The PSV features a 90l tank for pre-loading and storage of metal powder. The automatic system sieves material before transportation to the machine for the build process, collects overflow powder to be returned to the sieve during the build, and also connects to the PRS unpacking station for powder removal after completion of a build.

The finished build cylinder is transported out of the system. Cooling and removal of excess powder takes place inside the part removal station (PRS), so that the next build process can begin immediately.

Tool for visualizing thermal emission of melt pool in the SLM®process. The system records the thermal radiation produced from the melt during the entire production process.

- Sequential output of thermal emission plot images of individual layers

- Detect irregularities and defects in parts

- Log and document build jobs in MPM-Files

Permanent on-axis laser power monitoring system that measures and illustrates nominal and actual power during the ongoing manufacturing process.

- Active warnings, highlighting spots with critical laser power deviation

- Documentation of the laser power for each scan vector over the entire build job

Tool to level recoater height and adjust overlap area. Enables reproducible adjustments to the recoating lip height, independent from operator, within 1 μm. Resulting in recoating and the laser exposure level consistency for each build job.

Developed to simplify cleaning, maintenance and installation work on the SLM®Recoater.

- Stable mount for maintenance

- Safe handling

- Station features 360° rotation for full maintenance access

- Drip tray included for easy residual powder collection

- Safe storage of recoating mechanisms

- Station Dimensions: 730mm x 310mm x 250mm

Provides a consistent powder bed over thousands of layers and beneficial for efficient job changeover. Brush durability ensures stable recoating while enabling error correction during the build.

- Haynes 25 or IN718, tested and approved for use with any material

- Testing shows brush stability at over 100,000 layers

- In the event of a collision with an extrusion up to 3mm from the powder bed, the bristles bend and do not break.

- Allows for correction of a build defect without damage to either recoater or part

SLM®500 Technical Specifications

Build Envelope (L x W x H): | 500 x 280 x 365 mm |

3D Optics Configuration: | Twin (2x 400 W or 2x 700 W) IPG fiber laser Quad (4x 400 W or 4x 700 W) IPG fiber laser |

Build Rate: | up to 171 cm³/h |

Variable Layer Thickness: | 20 µm - 90 µm, more available on request |

Minimum Feature Size: | 150 µm |

Beam Focus Diameter: | 80 µm - 115 µm |

Maximum Scan Speed: | 10 m/s |

Average Inert Gas Consumption Process: | 16 l/min (argon) |

Average Inert Gas Consumption Purging: | 250 l/min (argon) |

E-Connection / Power Input: | 400 Volt 3NPE, 64 A, 50/60 Hz, 8-10 kW |

Compressed Air Requirement / Consumption: | ISO 8573-1:2010 [1:4:1], 6 bar |

Dimensions (L x W x H): | 5200 mm x 2800 mm x 2700 mm |

| Dimensions (L x W x H) | 6080 mm x 2530 mm x 2620 mm (incl. PSV & PRS) |

Weight: | 2400 kg excl. powder |